Two component adhesive

application system

Two component polyurethane adhesives for bonding a wide range of substrates. The curing process is predictable and controlled by reaction between the two components. The adhesive supplied as “resin” and “hardener” in separate drums or IBC containers. It is important to maintain the prescribed ratio of the resin and hardener in order to obtain the desired cure and physical properties of the adhesive.

The two components are only mixed together to form the adhesive a short time before application with cure occurring at room temperature.

Formulations are available with a variety of cure speeds providing various working times (Open time) after mixing and rates of strength build-up after bonding.

Adhesive must be cleaned from mixing and application equipment before cure has progressed to the point where the adhesive is no longer soluble.

Please download our PDF for more information

CONTACT US

TOGETHER WE VILL FIND THE RIGHT SOLUTION

Mikkel Karlsson

Sales Director

Phone: +45 44 844 11 33

Mail: mk@veta.dk

Address

Vetacs Adhesive Application Systems

Marielundvej 33

DK-2730 Herlev

Denmark

CALL US NOW

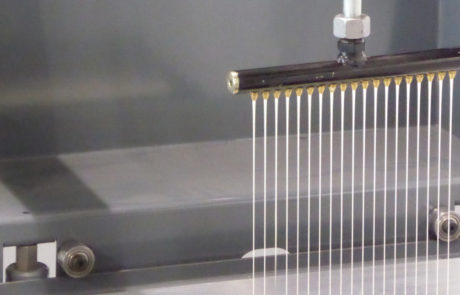

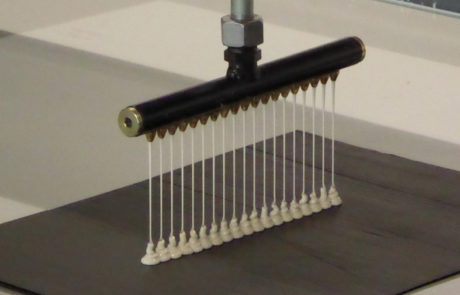

Industrial adhesive dispensing systems

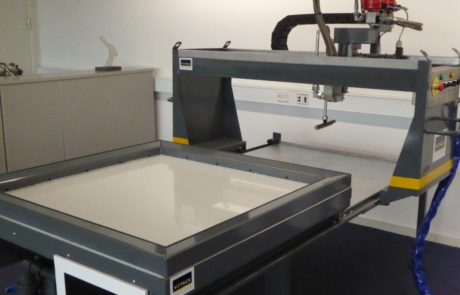

Besides the dispensing systems, VETACS also delivers lay-up tables with vacuum compression, conveyor and heated presses all designed and customized based on customer needs and requirements.

VETACS is a highly versatile manufacturer of industrial adhesive dispensing systems.

Our standard machine range starts with the simplest manually operated machine, over semiautomatic solutions to very advanced and fully automatic systems, and in some cases entire factory layouts.